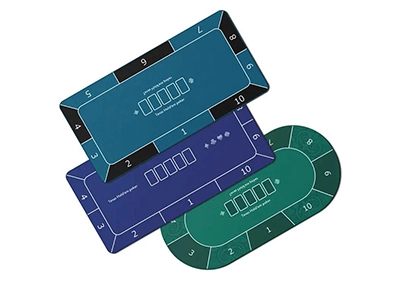

After receiving the original card design, the factory needs to re-layout it according to the size of the chosen paper material to minimize waste.

Once the layout is completed, printing plates are made based on the electronic layout. These plates, also known as printing plates, are used for offset printing.

The design is then printed using a Heidelberg printing machine, resulting in large sheets of cards with the designs printed continuously.

The printed products are coated with oil to protect the ink and prolong its color lifespan.

If additional processes such as UV printing, hot stamping, or embossing are required, they are carried out before the cards are cut. After these processes, the cards are cut into their final size using a cutting machine.

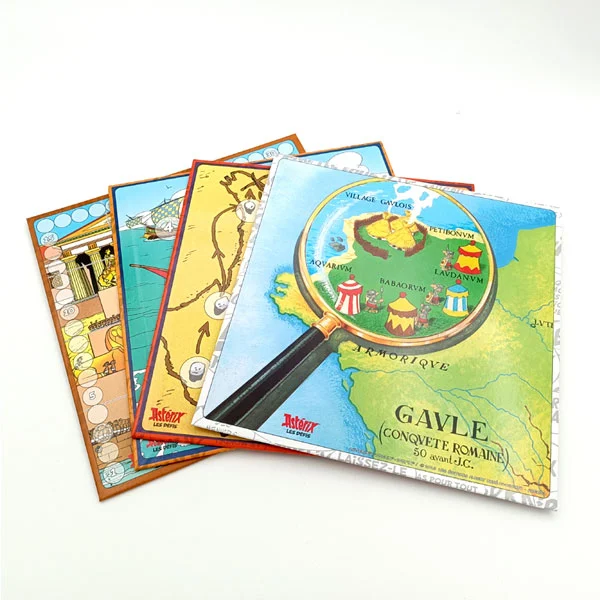

The cut sheets are then processed using an automatic sorting machine to separate the individual cards.

The cards undergo further detail processing, including rounding the sharp corners using a die-cutting machine and specific molds.

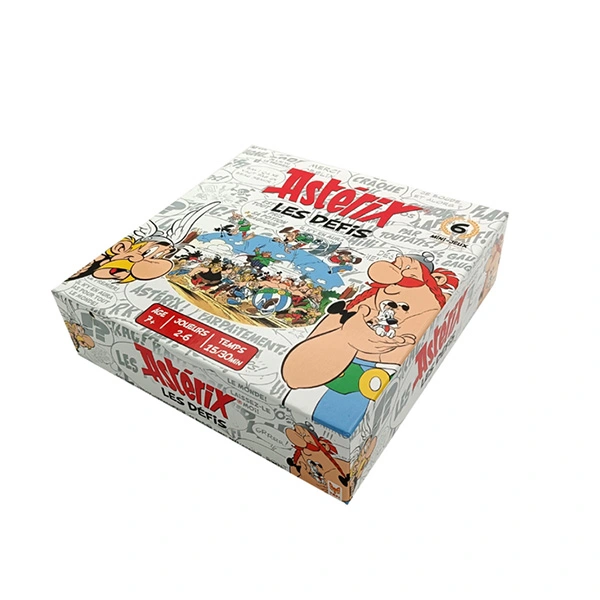

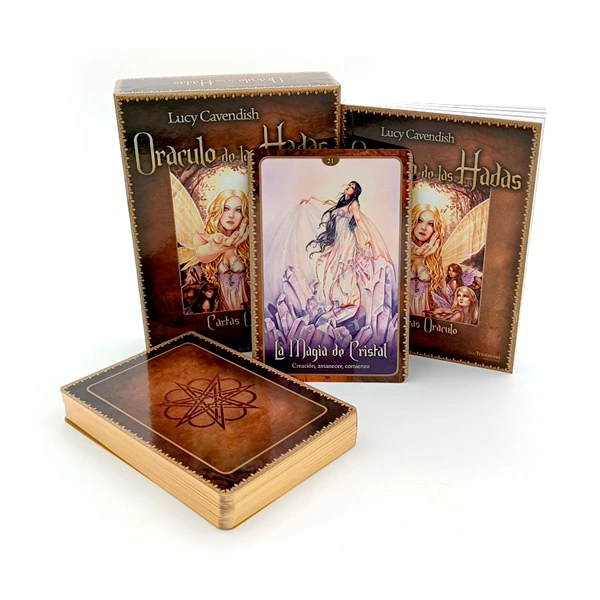

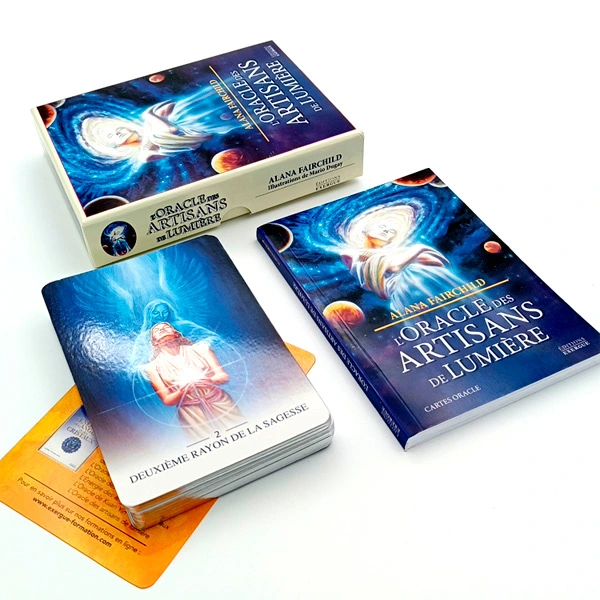

After all processing is complete, the cards are sealed and packaged before shipping.

This is the production process of board game cards in the factory. The production of a good card game requires strict control over each step and careful attention to detail. Only through rigorous standards and responsible work can a high-quality product be produced.