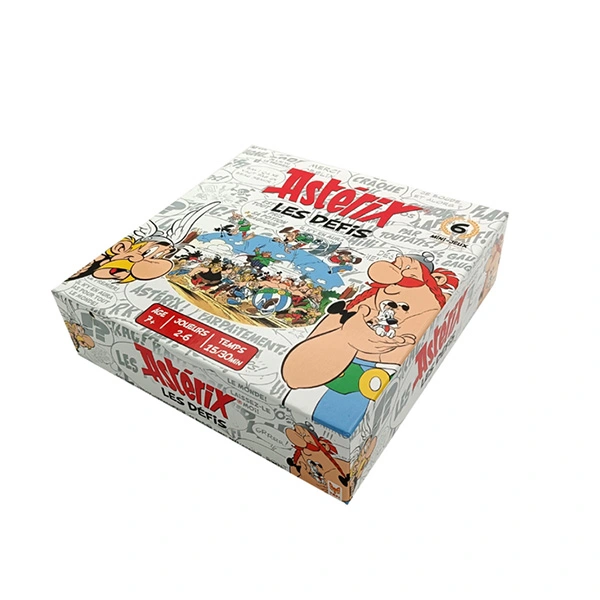

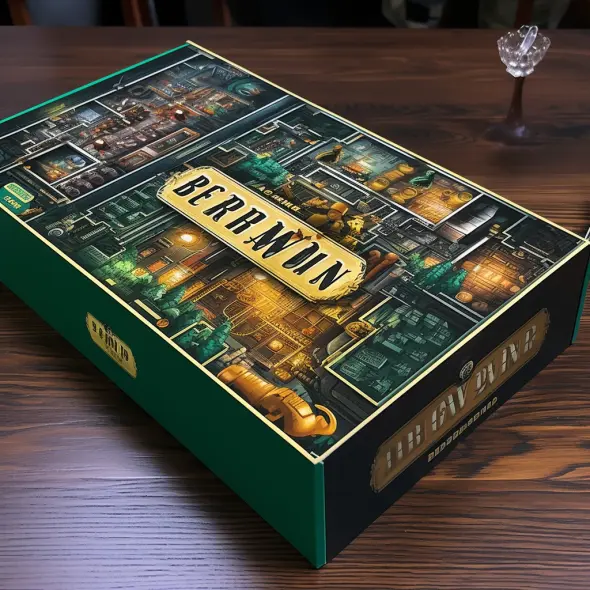

A board game's board is far more than a playing surface—it's the visual anchor of the game world and a functional foundation for gameplay mechanics, directly shaping player immersion and usability. Choosing the right board type, materials, and manufacturing approach is critical to balancing durability, cost-efficiency, and player experience, making it a defining factor in a game's commercial success. This guide breaks down the core elements of board game boards manufacturing to help enterprise customers make informed, strategic decisions.

Common Board Structures: Single-Piece vs. Folding

Single-piece boards offer unbroken visual continuity and seamless gameplay, eliminating issues like gaps or misalignment that could break immersion, making them ideal for games with complex, interconnected layouts. Their simplicity in design also reduces manufacturing complexity; however, due to their fixed size, they require larger packaging and higher shipping costs, making them less practical for portable or mass-market games. In contrast, Folding boards meet portability needs by folding into compact sizes, fitting easily into standard game boxes and thus lowering logistics costs. They come in various folding styles, such as bi-fold, tri-fold and gatefold, to accommodate different board sizes. Nevertheless, their hinges may loosen over time with frequent use, and fold lines may obscure artwork if not designed carefully. For games prioritizing table space efficiency or travel-friendliness, folding boards are the pragmatic choice, while single-piece boards excel for premium, immersive experiences where visual cohesion and structural stability take precedence.

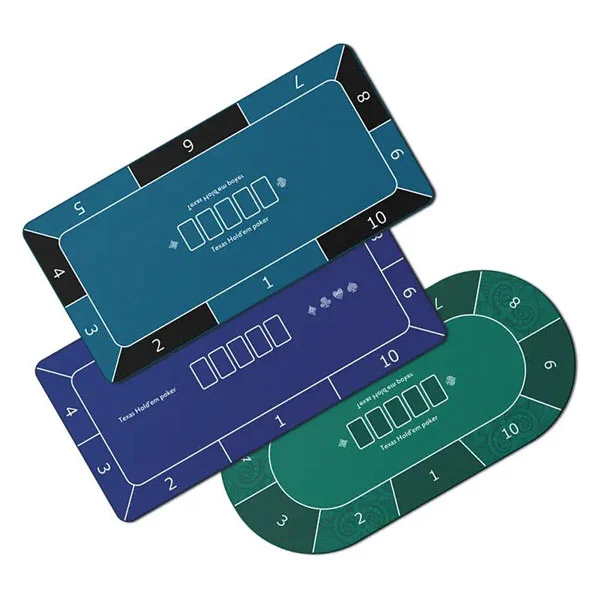

Core Materials: Chipboard, MDF, and Plastic Alternatives

Chipboard is the industry standard for most mass-produced board games, favored for its cost-effectiveness, lightweight nature, and ease of printing. Available in varying calipers, it balances rigidity and affordability. Thicker chipboardworks well for folding boards, while thinner variants suit simpler layouts. However, compared to denser materials, chipboard has lower durability and may warp or delaminate when exposed to moisture. MDF (Medium-Density Fiberboard) offers superior rigidity and durability, making it ideal for premium or heavy-use games. Its smooth surface ensures crisp print quality, though it is heavier and more expensive than chipboard, and requires careful handling during manufacturing to avoid splintering. Plastic alternatives (e.g., PVC, polypropylene) provide exceptional water resistance and durability, perfect for outdoor games or games targeting younger audiences prone to spills. They offer flexibility in shaping but come with higher production costs. For enterprise customers, chipboard is the go-to for cost-sensitive projects, MDF for premium positioning, and plastic for specialized use cases.

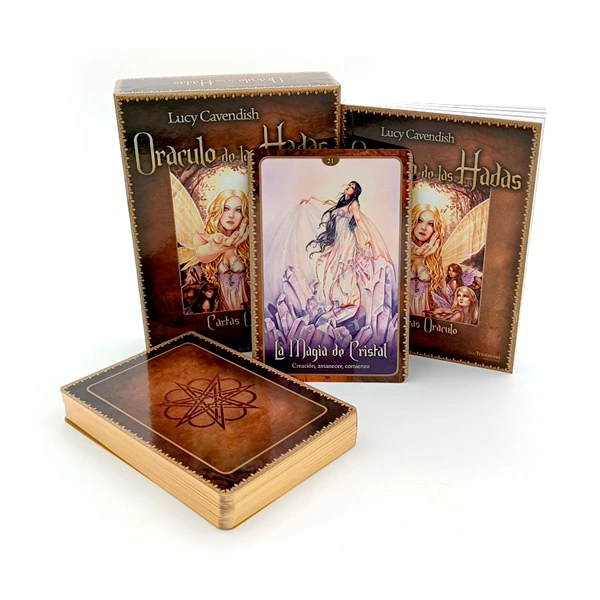

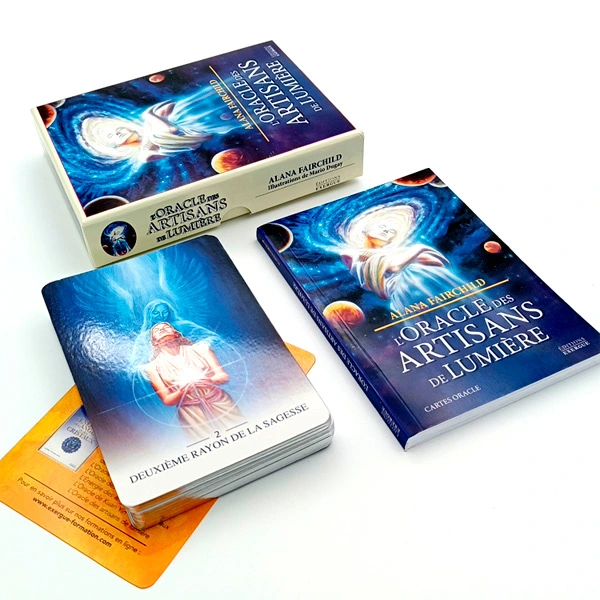

Finishing Styles: Matte, Gloss, and Linen Textures

Matte surfaces are a popular choice for strategy and euro-style games, as they minimize glare under various lighting conditions, ensuring clear visibility of text and artwork. They have a subtle, understated feel and resist fingerprint smudges, though they are slightly less resistant to scuffs than gloss finishes. Gloss finishes deliver vibrant, eye-catching colors that make thematic artwork pop, ideal for family-friendly or party games where visual appeal drives engagement. Their smooth, reflective surface is easy to wipe clean, but they can be prone to glare and show fingerprints more prominently. Linen textures combine the best of both worlds. Resembling linen fabric, they offer a tactile, premium feel, that enhances player engagement, while reducing glare and hiding minor smudges. Linen finishes are often associated with high-quality games, elevating the perceived value of the product, though they come at a slightly higher cost. The choice depends on the game's target audience: matte for focus-driven gameplay, gloss for playful, visually striking designs, and linen for premium positioning.

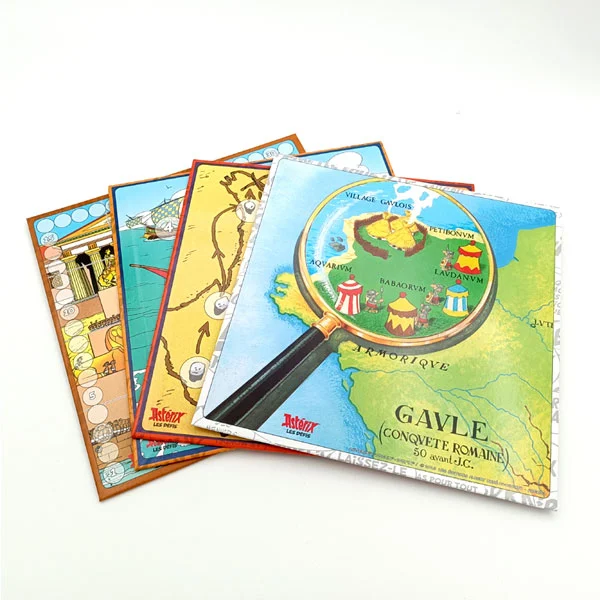

Size and Shape Customization for Unique Gameplay

Custom size and shape are powerful tools to reinforce gameplay mechanics and thematic identity. For example, a circular board can emphasize turn-based, cyclic gameplay, while irregular shapes can mirror in-game geography. Size customization should align with gameplay needs: larger boards (e.g., 24x36 inches) suit games with multiple players or complex layouts, while smaller boards (e.g., 12x12 inches) work for quick-play or travel games. Manufacturing considerations include tooling costs and packaging compatibility. Modular boardsconsists of interlocking components, offering flexibility that allows players to create unique layouts for each game, but requires precise manufacturing techniques to ensure tight and consistent fitting. For enterprise customers, balancing creative customization with production feasibility is key: start with standard sizes/shapes for cost efficiency, and invest in custom designs for games where unique geometry is central to core mechanics.

Board game board manufacturing hinges on four key decisions: structure (single-piece vs. folding), material (chipboard, MDF, plastic), finish (matte, gloss, linen), and customization (size/shape). Each choice impacts cost, durability, player experience, and brand positioning, requiring alignment with your game's target audience and core mechanics. Partnering with a manufacturer with expertise in both creative customization and industrial production ensures that your board not only meets design vision but also stands up to repeated use. Whether you're developing a mass-market family game or a premium strategy title, our team can help refine your board specifications, provide tailored recommendations, and deliver high-quality production. Contact us to discuss your project, request samples, or obtain a detailed quote. Let's bring your game's vision to life with a board that enhances every play session.